Introduction to VCSEL Technology

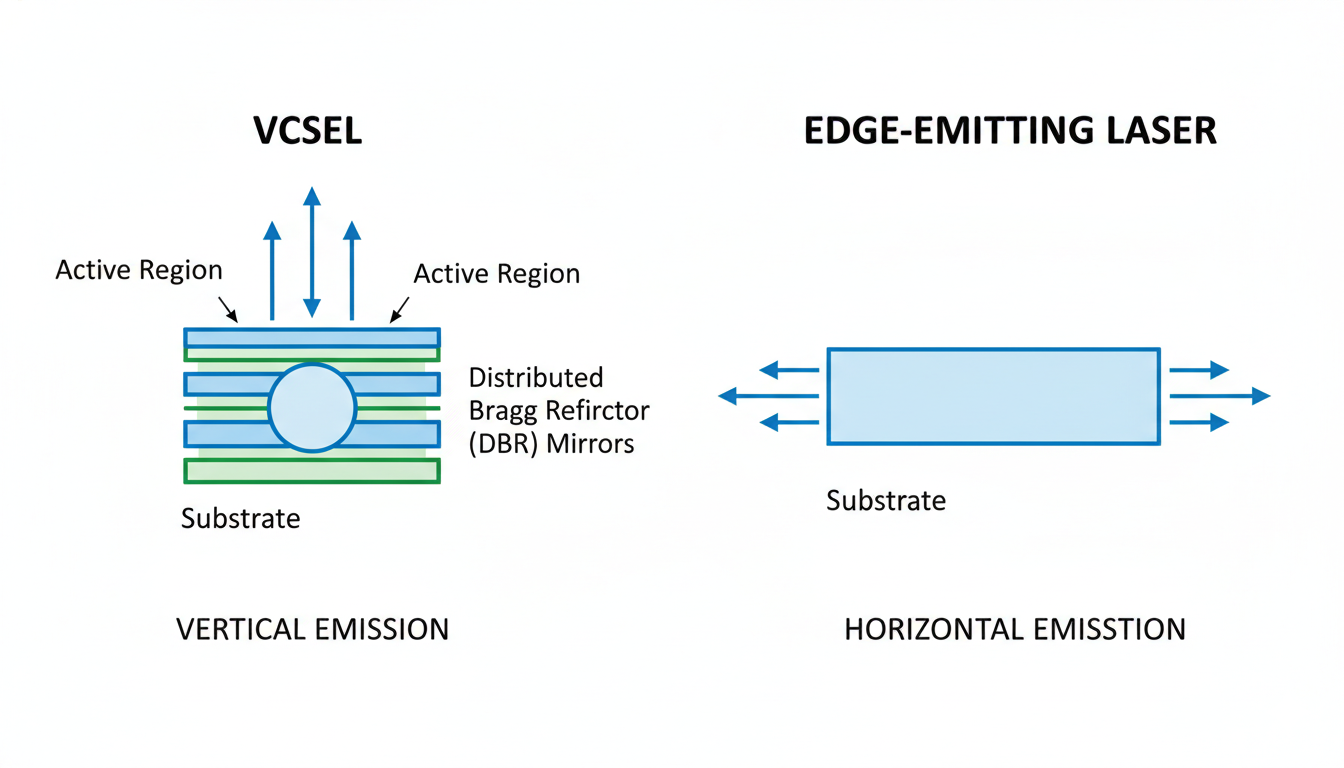

A VCSEL (Vertical Cavity Surface Emitting Laser) is a type of semiconductor laser diode that emits light perpendicular to the surface of the wafer, rather than from the edge as in conventional edge-emitting lasers. Since their commercial introduction in the 1990s, VCSELs have transformed multiple industries due to their compact size, low power consumption, excellent beam quality, and scalability.

Today, VCSEL technology is widely used in data communications, sensing, consumer electronics, industrial automation, automotive LiDAR, and biomedical devices. As global demand for faster data transmission and precise optical sensing continues to grow, VCSELs are becoming a cornerstone of modern photonic systems.

This article provides an in-depth, evergreen explanation of VCSELs, covering their working principles, structure, key advantages, applications, and future outlook.

What Is a VCSEL?

A Vertical Cavity Surface Emitting Laser is a semiconductor laser in which the optical cavity is oriented vertically relative to the wafer surface. Light emission occurs from the top surface, allowing devices to be tested and fabricated in large arrays directly on the wafer.

VCSELs typically operate in the near-infrared spectrum, most commonly at 850 nm, 940 nm, and 980 nm, though developments in red and short-wavelength VCSELs are ongoing.

Basic Structure of a VCSEL

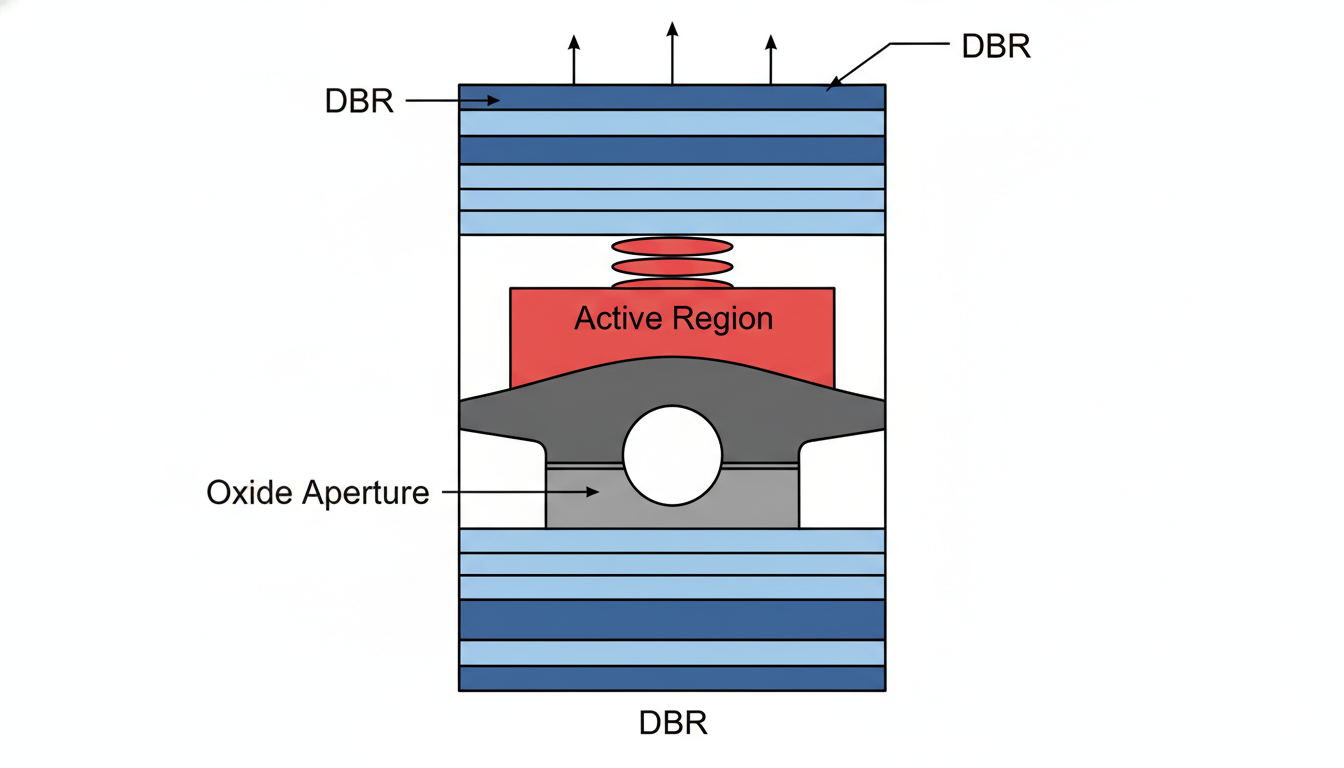

The structure of a VCSEL is fundamentally different from edge-emitting lasers. Key components include:

1. Active Region

The active region contains quantum wells where electron-hole recombination produces photons. The thickness of the active region is only a few micrometers, contributing to the short cavity length.

2. Distributed Bragg Reflectors (DBRs)

Two highly reflective mirrors—top and bottom DBRs—form the surface-emitting laser cavity. These mirrors consist of multiple alternating semiconductor layers with different refractive indices, achieving reflectivity greater than 99%.

3. Current Injection Layers

Electrical current is injected vertically through the device to stimulate photon emission in the active region.

4. Oxide or Ion-Implanted Aperture

This structure confines both current and optical modes, improving efficiency and beam quality.

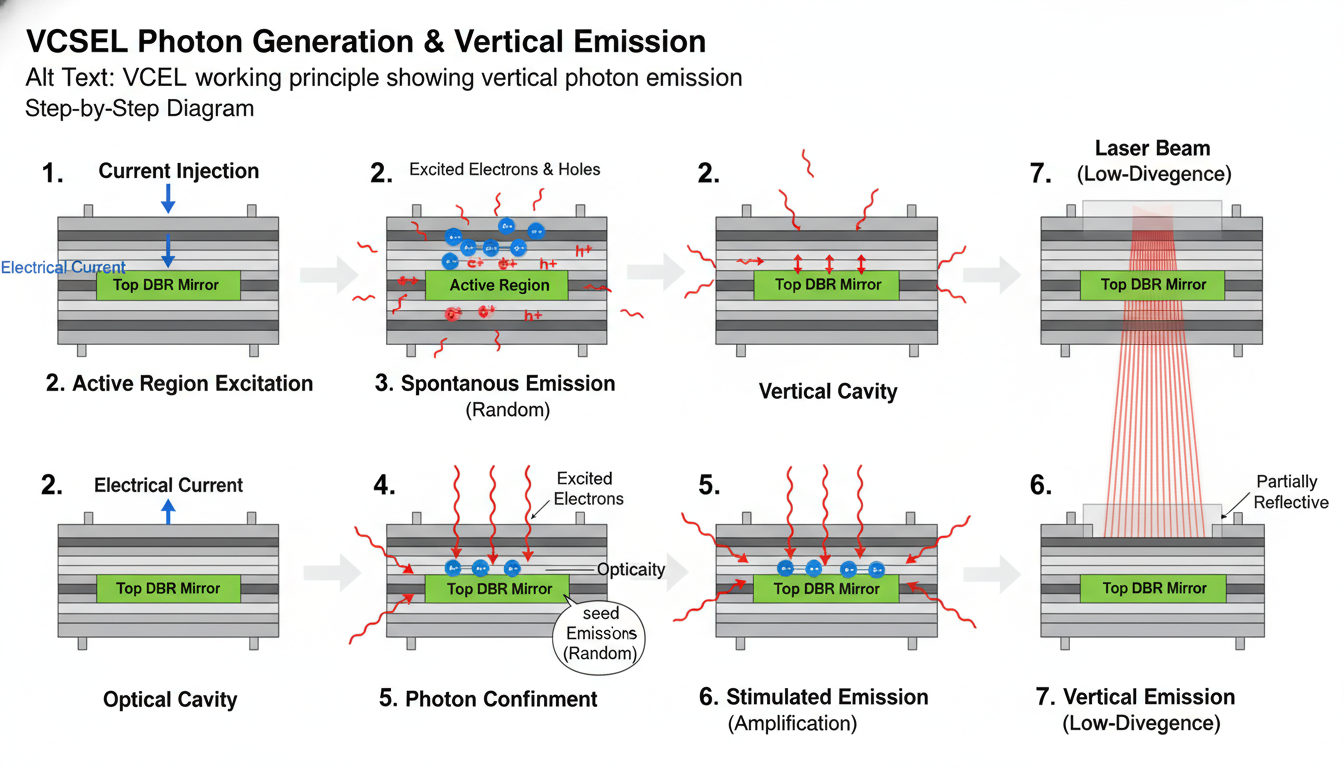

How a VCSEL Works

The operating principle of a VCSEL follows the standard laser process:

- Electrical current injection excites electrons in the active region.

- Stimulated emission occurs when excited electrons recombine with holes.

- Photons bounce vertically between the DBR mirrors, amplifying light.

- Coherent laser light exits perpendicular to the wafer surface.

The short cavity length enables single longitudinal mode operation, contributing to stable wavelength and narrow linewidth.

Key Advantages of VCSEL Technology

VCSELs offer several advantages over traditional edge-emitting lasers and laser diodes and other light sources:

1. Low Power Consumption

VCSELs operate efficiently at low threshold currents, making them ideal for battery-powered devices and large-scale deployments.

2. Circular, Low-Divergence Beam

The naturally circular output beam simplifies optical coupling and reduces the need for complex beam-shaping optics.

3. Wafer-Level Testing

Unlike edge-emitting lasers, VCSELs can be tested before dicing, significantly reducing manufacturing cost and improving yield.

4. High Reliability and Long Lifetime

VCSELs exhibit excellent thermal stability and reliability, often exceeding millions of hours of operational lifetime.

5. Scalable Arrays

VCSELs can be fabricated as 1D or 2D arrays, enabling high optical power and advanced sensing capabilities.

VCSEL vs Edge-Emitting Lasers

| Feature | VCSEL | Edge-Emitting Laser |

|---|---|---|

| Emission Direction | Surface-normal | Edge-emitting |

| Beam Shape | Circular | Elliptical |

| Testing | Wafer-level | After cleaving |

| Power Scaling | Via arrays | Limited |

| Packaging Cost | Lower | Higher |

While edge-emitting lasers and laser diodes excel in high-power and long-distance telecom applications, surface-emitting VCSELs dominate short-reach, high-volume, and sensing-based markets.

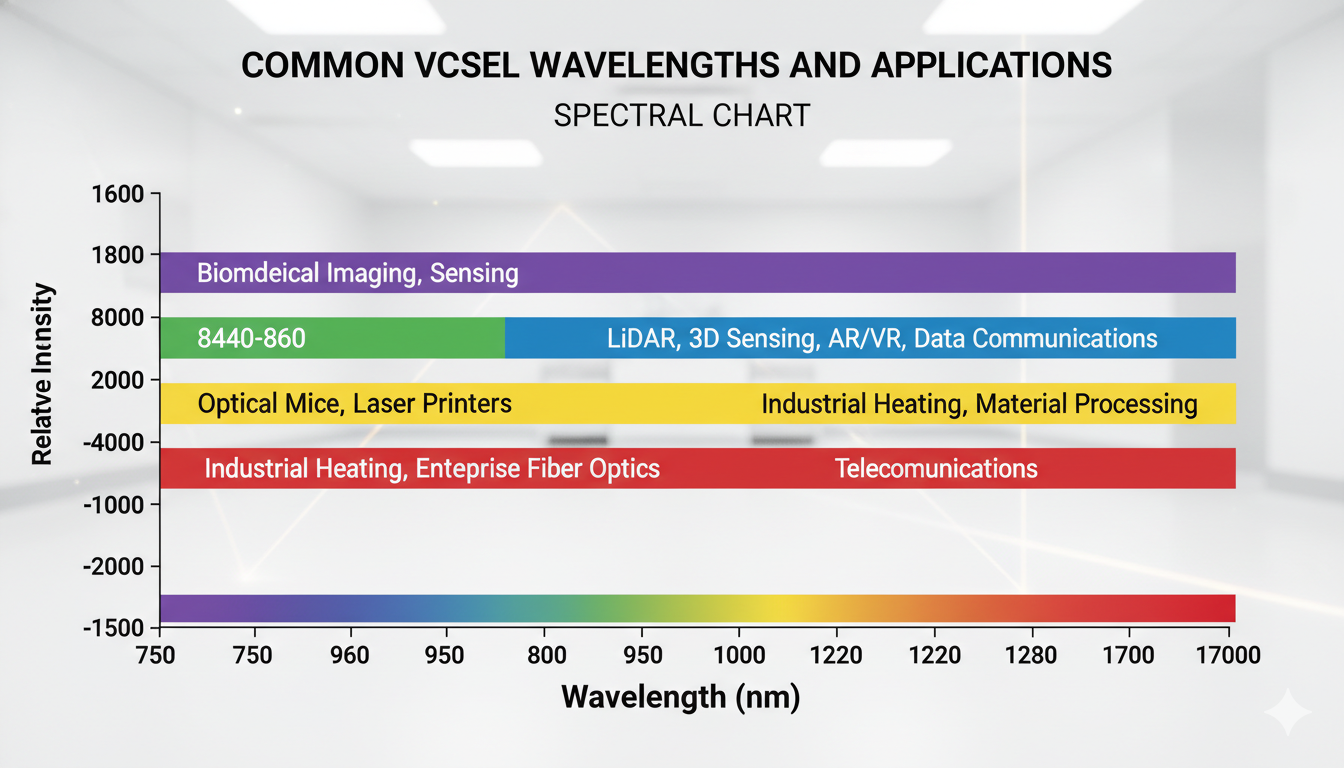

Common VCSEL Wavelengths and Materials

VCSEL performance depends on semiconductor material systems:

- 850 nm VCSELs: GaAs-based, widely used in data centers

- 940 nm VCSELs: Popular for 3D sensing and LiDAR

- 980 nm VCSELs: Used in pumping and sensing applications

- Red VCSELs (650–690 nm): Emerging for visible applications

Each wavelength range serves specific optical and system-level requirements.

Major Applications of VCSELs

1. Data Communications and Optical Interconnects

VCSELs are a backbone technology in short-reach optical communications, particularly in data centers and high-performance computing. Operating at 850 nm, VCSELs paired with multimode fiber enable:

- 10G, 25G, 50G, and 100G Ethernet links

- Low latency and high energy efficiency

- Compact optical transceivers (SFP, QSFP)

Their ability to support parallel optical channels makes them ideal for scaling bandwidth.

2. 3D Sensing and Facial Recognition

VCSEL arrays are widely used in structured light and time-of-flight (ToF) systems for 3D sensing. Key applications include:

- Smartphone facial recognition

- Gesture recognition

- Augmented and virtual reality (AR/VR)

VCSELs provide precise, uniform illumination patterns essential for accurate depth mapping.

3. Automotive LiDAR and ADAS

In the automotive sector, VCSELs are gaining traction for LiDAR (Light Detection and Ranging) systems used in:

- Advanced driver-assistance systems (ADAS)

- Autonomous vehicles

- Object detection and ranging

Compared to edge-emitting lasers, VCSEL arrays offer improved eye safety, reliability, and scalability.

4. Industrial Sensing and Automation

VCSELs are used in industrial environments for:

- Proximity sensors

- Optical encoders

- Machine vision

- Precision distance measurement

Their stable wavelength and fast modulation support high-speed, high-accuracy sensing.

5. Biomedical and Healthcare Applications

In biomedical instrumentation, VCSELs enable:

- Optical coherence tomography (OCT)

- Pulse oximetry

- Flow cytometry

- Medical imaging and diagnostics

The compact size and low heat generation make VCSELs suitable for portable and wearable medical devices.

Performance Characteristics of VCSELs

Key parameters engineers consider when selecting VCSELs include:

- Output power

- Threshold current

- Slope efficiency

- Beam divergence

- Modulation bandwidth

- Wavelength stability

Modern VCSELs can achieve modulation speeds exceeding 25 GHz, supporting high-speed optical links and advanced sensing applications.

Thermal Management and Reliability

Thermal performance is critical in VCSEL operation. Advanced designs incorporate:

- Efficient heat spreading layers

- Optimized DBR structures

- Improved packaging materials

These innovations enhance reliability, reduce wavelength drift, and ensure consistent performance over temperature variations.

VCSEL Manufacturing and Packaging

VCSEL fabrication leverages mature semiconductor manufacturing processes, including:

- Molecular beam epitaxy (MBE)

- Metal-organic chemical vapor deposition (MOCVD)

- Wafer-level packaging

This enables high-volume production with tight tolerances, supporting cost-effective deployment in consumer and industrial markets.

Future Trends in VCSEL Technology

The future of VCSELs is driven by increasing demand for speed, efficiency, and integration:

- Higher-power VCSEL arrays for LiDAR

- Longer wavelength VCSELs for sensing and spectroscopy

- Integration with silicon photonics

- AI-driven optical sensing systems

- Expanded use in smart devices and IoT

As photonic integration advances, VCSELs will remain a key enabler of next-generation optical systems.

Conclusion

The VCSEL (Vertical Cavity Surface Emitting Laser) and laser diodes are among the most versatile and impactful surface-emitting laser technologies in modern photonics. Its unique vertical emission structure, low power consumption, scalability, and high reliability make it indispensable across industries ranging from data communications to automotive LiDAR and biomedical diagnostics.

As technology continues to evolve, VCSELs will play an even greater role in enabling faster data transfer, smarter sensing, and more compact optical systems. Their evergreen relevance ensures that VCSEL technology will remain a foundational component of the global photonics ecosystem for decades to come.