Semiconductor lasers such as FP, DFB, VCSEL and more are essential devices for regulating and improving the Internet and communication sector in the world. Laser’s outstanding properties such as high efficiency of the electrical energy into photons, excellent reliability, small footprint, modulation bandwidth, and low cost have made it a principle component in various communication applications.

VCSEL or Vertical Cavity Surface Emitting Laser is one such laser that is largely used in various industrial and military applications. This article discusses the basics of VCSEL, including its definition, working and characteristics. Also, we will explore the applications, and advantages it offers, along with its inherent limitations.

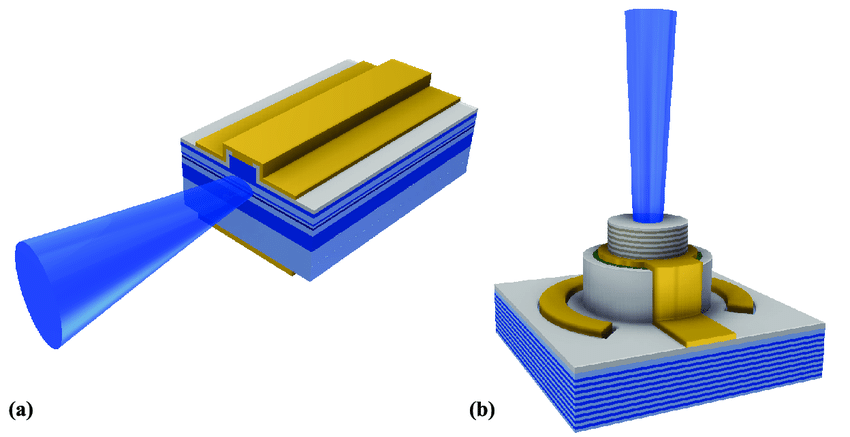

Wikipedia defines VCSEL as the type of semiconductor laser diode with laser beam emission perpendicular from the top surface, as opposed to conventional edge-emitting semiconductor lasers which emit from surfaces.

In simple words, compared to conventional edge-emitting light diodes, VCSEL emits light or a vertical beam from its top surface.

Now let us comprehend how Vertical Cavity Surface Emitting Laser works. Note that, as it is challenging to cover the whole working process in detail, we have covered fundamental points only.

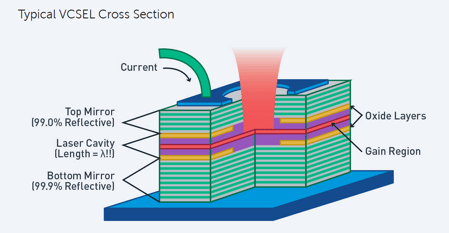

A typical Vertical-Cavity Surface-Emitting Laser is made of several layers. The top is a layer in electrical contact for current injection. The next layer, i.e. the second layer, is the high-reflectivity mirror with 99% reflectivity. The next– third layer is an oxide layer that develops a light-emitting window so that the light beam can be converted into a circular beam.

The next layer– the centre layer in the VCSEL is the laser cavity. It is the active gain region where lasing happens. Again there is an oxide layer below the center layer to confine the light. And the last layer is again a DBR– distributed Bragg reflector and the last– bottom layer is a reflective mirror with 99.9% reflectivity.

Note that the bottom mirror has more reflectivity than the top mirror so that lasing light can get out from the top mirror instead of the bottom mirror.

The quantum wells generate photos that travel between the top DBR mirror and the bottom DBR mirror. This lasing mechanism remains the same in every laser. The quantum well is made of three layers–a very thin gallium arsenide layer sandwiched between two thick aluminium gallium arsenide layers. This structure produces quantum confinement– an effect to increase lasing efficiency.

Now, let us learn about some of the significant characteristics of the VCSEL, which makes it a preferred option for a variety of medical, industrial and military applications.

Optical Data Transmission in Data Centers: VCSELs play a vital role when high-speed optical data transmission is enabled within data centers. The lasers are used to transmit vast amounts of data through fiber-optic cables. Thereby ensuring faster and more efficient communication between servers and networking equipment. The VCSELs are utilized for their ability to modulate data at extremely high speeds making them indispensable components in modern data centers.

Role of VCSELs in Fiber-Optic Communication: VCSELs are instrumental in long-distance fiber-optic communication networks, in addition to data centers. Their efficiency of light emission and ability to couple with optical fibers facilitate data transfer over considerable distances without significant signal degradation. The application of VCSEL has significantly enhanced the speed and reliability of global communication systems.

3D Sensing and Facial Recognition: VCSELs have their powering facial recognition systems in smartphones and other devices. The structured light emitted by VCSELs is used to capture accurate depth information which enables sophisticated facial recognition and augmented reality experiences. Additionally, there are wide applications in gesture recognition and immersive gaming.

Advancements in LiDAR Technology using VCSELs: LiDAR (Light Detection and Ranging) systems, crucial for autonomous vehicles and environmental mapping, benefit from VCSEL technology. VCSEL-based LiDAR when compared to traditional systems offers higher resolution, improved range, and faster response times. Allowing autonomous vehicles to navigate complex environments more safely and efficiently.

VCSEL Applications in Optical Mouse and Touchless Sensors: VCSELs are widely used in optical mouse to track movement accurately and smoothly on various surfaces. The coherent light emission from VCSEL enables precise tracking, making them a popular choice for modern computer peripherals. Usage of VCSELs for reliable and contactless detection of objects or individuals, their touchless sensors, are commonly found in public facilities.

Use of VCSELs in Printing and Scanning Devices: Having found their way into printing and scanning devices, the VCSELs contribute to high-quality, high-speed printing and scanning processes. Their ability to emit light at specific wavelengths makes them ideal for laser printing, enabling crisp text and detailed images. Moreover, VCSELs enhance the performance of scanning devices by providing accurate and consistent scanning results.

Energy Efficiency and Low Power Consumption: Energy efficiency is regarded as one of the most significant advantages of VCSEL along with lower power consumption. Their ability to convert electrical energy into coherent light with remarkable efficiency, resulting in lower power consumption compared to other laser technologies is exceptional. This characteristic is essential in portable devices and data centers, where energy conservation is a priority.

Compact Size and Ease of Integration: The integration of VCSEL compact design into various electronic devices and systems is seamless. Their small form factor allows for making them suitable for space-constrained applications and facilitating the development of miniaturized electronic products.

High Reliability and Long Operational Lifespan: VCSEL is known for its outstanding reliability and longevity. They exhibit a stable performance over extended periods, making them ideal for mission-critical applications that require consistent operation without frequent maintenance.

Thermal and Power Handling Challenges: VCSEL tends to generate heat during operation, which may slightly affect its performance and reliability. Management of the heat generated and ensuring proper heat dissipation becomes essential to prevent thermal degradation and maintain optimal performance of the laser. Moreover, VCSELs may carry limitations in handling high-power applications due to potential thermal issues.

Manufacturing Complexities and Costs: The manufacturing process of VCSELs can be complex and costly requiring expertise and involving intricate semiconductor fabrication techniques. As a result, VCSELs may have higher production costs compared to some other laser technologies. However, advancements are ongoing in the sector of manufacturing processes to gradually reduce these costs.

At InPhenix, we take immense pride in providing technology-oriented solutions. With our cutting-edge VCSEL technology, a game-changer hitting the market, it has revolutionized numerous industries. As we explore the diverse applications, advantages, and limitations of VCSELs in this comprehensive guide, it is evident that these lasers have paved the way for remarkable advancements in data communications, sensing, imaging, and consumer electronics.

At InPhenix, we recognize the importance of reliability and longevity in critical applications, thus striving for innovation. Our VCSELs exhibit exceptional performance and long operational lifespans, ensuring consistent and stable operation without frequent maintenance.

While VCSELs offer remarkable advantages, we understand the challenges they face. Thermal and power handling considerations are critical, and we are dedicated to addressing these challenges through our continuous research and development efforts. Our commitment to improving manufacturing processes also ensures that our VCSEL solutions remain cost-effective without compromising on quality and performance.

Choose InPhenix for pioneering VCSEL technology that empowers industries with unmatched precision, efficiency, and reliability. Our cutting-edge VCSEL solutions drive innovation and shape the future of various sectors, providing transformative solutions for a rapidly evolving world.

In the next blog, we will cover more about VCSEL applications in detail. Keep following Inphenix.

Inphenix is a laser and light source manufacturing company headquartered in California, USA. The company develops a range of optic devices, lasers, and light sources including distributed feedback lasers, superluminescent diodes, Fabry-Perot lasers, swept source lasers, and VCSEL, among others.